Good forests as Climate Solutions: How do rainforests store CO2 in the long term?

“Buildings and the construction sector together account for 40% of total direct and indirect CO2 emissions.”

(Global Status Report for Buildings and Construction, 2019)

This figure is quoted by the renowned climate impact researcher Hans-Joachim Schellnhuber – Director of the Potsdam Institute for Climate Impact Research – to the Baden-Württemberg Chamber of Architects in December 2020.

He explicitly points out that the use of concrete and steel in the construction sector has a catastrophic, even unsustainable climate balance. This is simply because the production of steel and cement releases vast amounts of CO2 as an additional product. He concludes, finally, that there is only one sensible vision for the future of the construction sector: “buildings as a global carbon sink,” buildings made of wood.

“Carbon sink” is a term used to describe ecosystems and man-made constructions that can absorb CO2. These include the world’s oceans, global forest areas, and agricultural croplands. The goal of reducing atmospheric CO2 levels has long been about increasing the so-called sink capacity of natural sinks so that more CO2 can be sequestered in an efficient, long-term and socially acceptable manner. And it is precisely this mechanism that is reflected in the new mission of Fairventures Worldwide: “Good Forests as Climate Solution”. In other words, Fairventures Worldwide is not simply a reforestation organization. Fairventures is an organization that increases the nature-based sink capacity of the forest ecosystem (tropical rainforest) by reforesting fallow land, thus creating ecosystems that absorb more CO2 and ultimately counteract global warming. But how does this sink capacity work in forests?

‘Forests are the lungs of the earth’, everyone knows that. But why? First, it’s because trees – with the help of sunlight and carbon dioxide – photosynthesis. So, in order to grow and thrive, they need sunlight and carbon dioxide, in addition to sufficient nutrients and water. In the process of photosynthesis, the tree splits oxygen from carbon. It retains the carbon and uses it to build its robust biomass: its root system, trunk, bark, branches and leaves. It gives the oxygen to the world to breathe. This is – simplified – the natural carbon cycle of the forest ecosystem and the reason why trees and forests are world champions in absorbing atmospheric CO2. It is also the reason why we at Fairventures are so convinced of the nature-based climate solution “reforestation”.

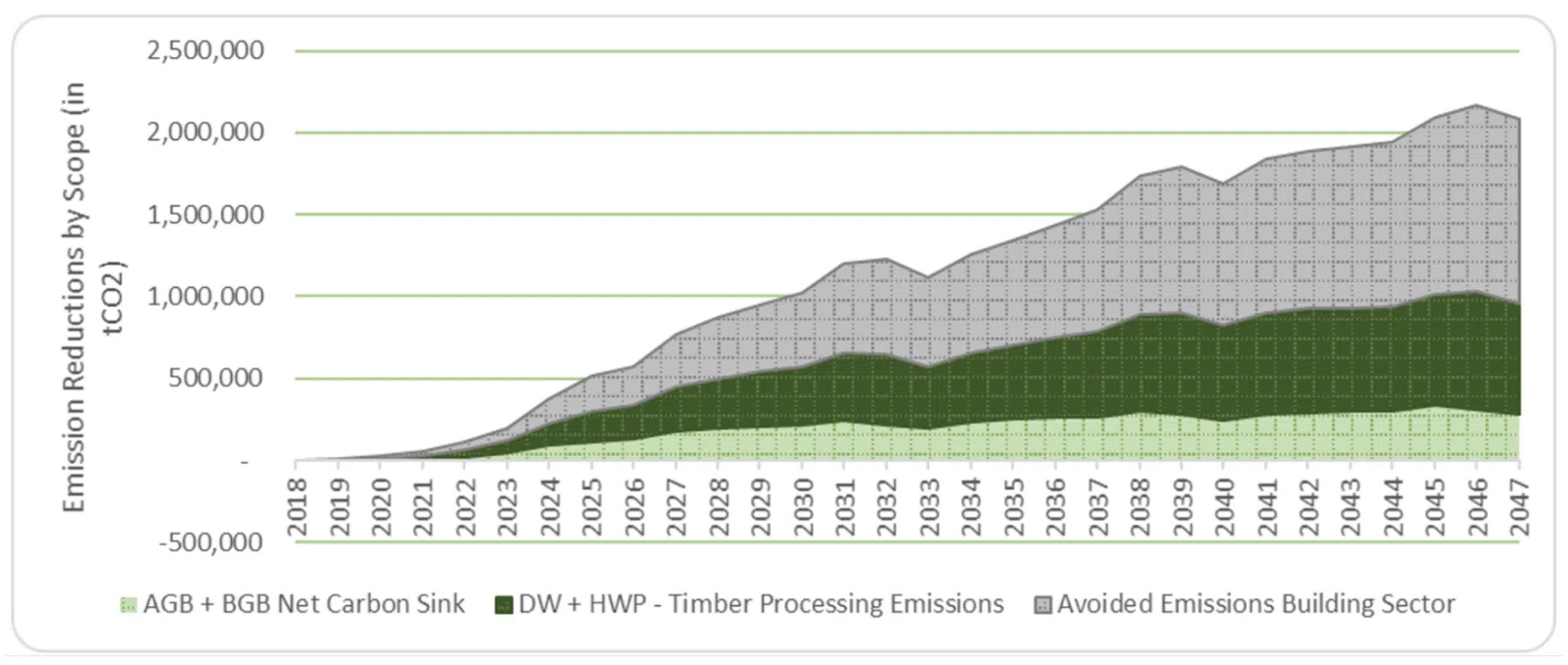

But that’s not enough for us at Fairventures. We want to follow the findings of Hans-Joachim Schellnhuber and many other climate researchers and link the sink effect of the forest with the building sector. That is why we at Fairventures have worked out a longer-term approach that fully exploits the sink performance of wood as a raw material. The chart below depicts this three-part sink performance: The first sink performance occurs directly on the cropland. Trees absorb atmospheric CO2 through photosynthesis, and store the carbon in their biomass (both below and above ground) and release the oxygen. The second sink benefit occurs after trees are harvested from Fairventures growing areas. Depending on the tree species and local climate, this occurs after 7-10 years. The tree is harvested and sold to the timber industry. Here, the first stop is the sawmill. At this point, the roots have already been cut off; now the bark, branches and leaves follow. In technical jargon, we speak of “biomass conversion factor” or simply “loss factor” to describe how much biomass is lost from the tree in the wood processing process. According to our model, this is up to 55% of the biomass. This is often used as firewood or as basic fertilizer on new land. In addition, there is the possibility of converting the biomass residues into biochar. Biochar is used to increase the fertility of intensively cultivated soils. For this purpose, a pyrolysis process is used in which large parts of the residual wood are carbonized and can thus be returned to the soil as fertilizer. Thus, the positive effect is twofold: on the one hand, the biochar acts as an enrichment of the soils, on the other hand, the biochar still stores the carbon from the biomass residues. Thus, it reduces emissions from the wood industry.

Nonetheless, these biomass residues create new, unavoidable emissions. At the same time, there is an industry behind wood processing that currently still relies largely on fossil fuel sources. These emissions must be taken into account in the calculation. What remains is the sink performance of the finished processed product, such as boards, beams, or veneers. Both of these sink efficiencies are active reductions of CO2 in the atmosphere. It is the direct result of the absorption of carbon dioxide and its long-term storage in the biomass of trees and the wood products made from them. The last sink performance has a different character. It does not describe an active reduction of atmospheric CO2, but an emission reduction or a prevention of further emissions. In technical jargon, this sink effect describes a substitution effect, namely the emissions prevented if steel and concrete are no longer used as construction materials in the building sector, but instead the harvested wood is used. The wood that is now stored in durable homes not only serves as a long-term carbon sink, but at the same time prevents further emissions from the use of energy-intensive raw materials. As we can see, this substitution effect is enormous and has become indispensable to ambitious climate protection strategies.

The graphic above stems from our own carbon calculations. The lowest level models the primary carbon sink potential of the standing biomass in the fields. The middle level represents the modeled carbon storage in the timber construction sector and already includes emissions from timber processing. The top level displays the avoidance of emissions that would theoretically occur if the subsequent construction had not been carried out with timber, but with steel and cement.

How all these sink benefits will develop in the future depends on a variety of factors. Will we be able to raise enough capital to make the renewable resource wood prominent in the building sector? Will we be able to mobilize ambitious political will against an old-guard lobby from the steel and concrete construction, and fossil fuel industries? Will we as a society initiate and accept a cultural-aesthetic change in the sense of an ecologically sensible and socially compatible architecture that recognizes and promotes – even embraces – wood as a sustainable building material?